Thanks to our 5 production sites and 1 logistic hub located in Italy, Slovakia and Mexico, Brovedani Components ensures know-how and mirror production on two continents, to meet the current requirements of the automotive and non-automotive industries.

In 1947, Silvio Brovedani founded a small workshop in the Pordenone area. In 1972, the company was taken over by S.p.A. constituted by Benito Zollia; this new impulse marks the beginning of a long evolution that takes us to the present day.

Brovedani Slovakia Sro was founded in 2004 and since 2006 has been operating in the new plant in Galanta (Slovakia), from this site it is satisfied the ever-growing demand for supplies located in Eastern Europe.

In 2008, the Brovedani Group and Reme (a Mexican company founded in 1965 with headquarters and production in Querétaro), signed a joint venture agreement founding Brovedani Reme Mexico, nowadays 100% owned by Brovedani Group Spa.

ITALY – San Vito al Tagliamento – PROD1

Headquarter - Development & production

Year

Factory

foundation

Prod. Area

smq

tot. surface 38k

Employees

of which 11%

are apprentices

Production

million

pieces

Main production

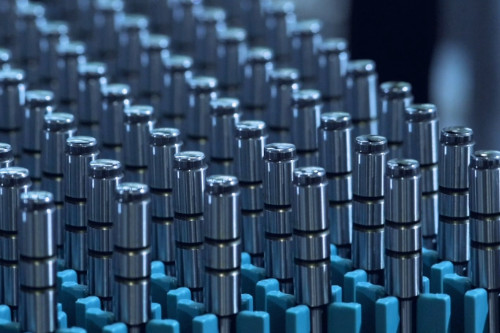

This facility is specialized in the series production of precision mechanical components with multispindle and superfinishing technologies such as hard turning and grinding.

ITALY – San Vito al Tagliamento – PROD2

Development and production

Year

Factory

foundation

Prod. Area

smq

tot. surface 10k

Employees

of which 8%

are apprentices

Production

million

pieces

Main production

Plant focused on complementary processes such as centreless grinding, lapping, honing, polishing, induction hardening, electrochemical deburring, assembly etc. .

ITALY – San Vito al Tagliamento – LOGISTIC HUB

Supply chain & logistic operations

Year

Factory

foundation

Prod. Area

K smq

tot. surface 35k

Employees

Shipments

thousand

year

Main production

The new global challenges and the huge number of customers facilities served from Italy has led us to create a dedicated plant focused on logistic. With our multi language supply chain team, we are able to satisfy our worldwide customers’ requirements.

ITALY – Modugno – BARI

Development and production

Year

Factory

foundation

Prod. Area

smq

tot. surface 28k

Employees

of which 7%

are apprentices

Production

million

pieces

Main production

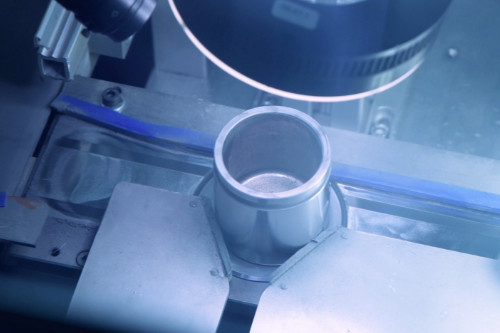

Bari plant is specialized in pistons for brakes application. Thanks to our on-site chrome plating line, as well as our precision mechanical machining, mechanical multispindle machines and CNC transfers machines we are able to finish in house the production of our components.

SLOVAKIA – Galanta

Headquarter - Development & production

Year

Factory

foundation

Prod. Area

k smq

tot. surface 20k

Employees

of which 12%

are apprentices

Production

million

pieces

Main production

This facility is well furnished to support also small & medium batches though the utilisation of CNC dual spindles or vertical spindle machines. For high production series Brovedani Slovakia can trust on precision mechanical machining, CNC transfers, grinding machines, induction hardening systems and rolling machines

MEXICO – Querétaro

Headquarter - Development & production

Year

Factory

foundation

Prod. Area

K smq

tot. surface 30k

Employees

of which 8%

are apprentices

Production

million

pieces

Main production

This facility follows the flow of USMCA challenging with the high quality requirements that customers are asking for. The workshop is well equipped to support small, medium and high batches through the usage of CNC and Swiss-Type turning machines, multispindle turning machines, mechanical & CNC transfer machines, working canters. Finishing operations as centreless grinding and auxiliary machining such as rolling and induction hardening are available.